2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

function

function

quality

quality

Technology mature

Technology mature

Stable performance

Stable performance

Aeronautics and astronautics

Aeronautics and astronauticsAerospace is one of the most active and influential fields of science and technology in the 21st century. The great achievements in this field mark the latest development of human civilization and represent the advanced level of a country's science and technology. As a cutting-edge advanced manufacturing technology, metal 3D printing has become an important driving force of the global new round of scientific and technological revolution and industrial revolution, constantly moving closer to cutting-edge manufacturing. Metal 3D printing opens a new manufacturing door for aerospace manufacturing. It ADAPTS to the rapid development of complex and high-precision construction in aerospace, efficient and rapid production of special-shaped parts, structural optimization, innovative lightweight design, and rapid repair of damaged parts.

Mould manufacturing

Mould manufacturingAs an important means of modern manufacturing technology, mold plays an extremely important role in the mass production and manufacturing of automobiles, electronics, consumer goods, household appliances and so on. Traditional die manufacturing processes such as NUMERICAL control machining, edM, precision casting, etc., have been widely used for a long time. With the continuous improvement of product quality requirements, traditional manufacturing technology is increasingly difficult to meet the quality requirements of high-end precision molds. Because of 3 d printing technology won't be in the process of manufacturing products internal structure and shape of the complex constraints, complex accompanying by inside the mold cooling waterway design and processing, 3 d printing technology can easily achieve high-end mold manufacturing, metal application of 3 d printing technology makes the design of the mold highly flexible, easily implement complex structure, The realization of scale customization, from design to direct production of digital products, drives the production of mold products to customization and complexity.

Education scientific research

Education scientific researchWith the further development and maturity of intelligent manufacturing, new information technology, control technology and material technology have been widely applied to the manufacturing field, and 3D printer technology will also be pushed to a higher level. The development of 3D printing technology will reflect the trend of precision, intelligence, universality and convenience. 3D printing technology has been attached great importance by the country in the field of education and scientific research. The launch of "National Additive Manufacturing Industry Development And Promotion Technology (2015-2016)" has raised the development plan of 3D printing technology to the height of national strategic development. It not only emphasizes the promotion and popularization of 3D printing education, but also emphasizes the cultivation of 3D printing technology talents. The 14th Five-Year Plan of China proposes to build a high-quality education system and enhance the adaptability of vocational and technical education. We should highlight the characteristics of vocational and technical education, deepen reform and innovation, optimize the structure and distribution, and vigorously train technical and skilled personnel. In 2015, the Ministry of Education listed "3D Printing of aviation products", "Additive manufacturing Technology" and other professional directions in the higher vocational education (specialty) directory, and in 2020, additive manufacturing engineering was listed in the general higher education (undergraduate) directory. 3D printing education in secondary vocational education, higher vocational education and general higher education, for different levels of additive manufacturing personnel training system is constantly improved. 3D printing technology has special application value and research direction in the application of new materials for scientific research, the study of structural and mechanical properties, the materialization of microstructure, structural topology optimization design and so on. It is also a major feature of scientific research in the fields of various materials forming. From the direction of scientific research and technology application and national talent cultivation, 3D printing is promoted to be more widely applied in the field of education and scientific research.

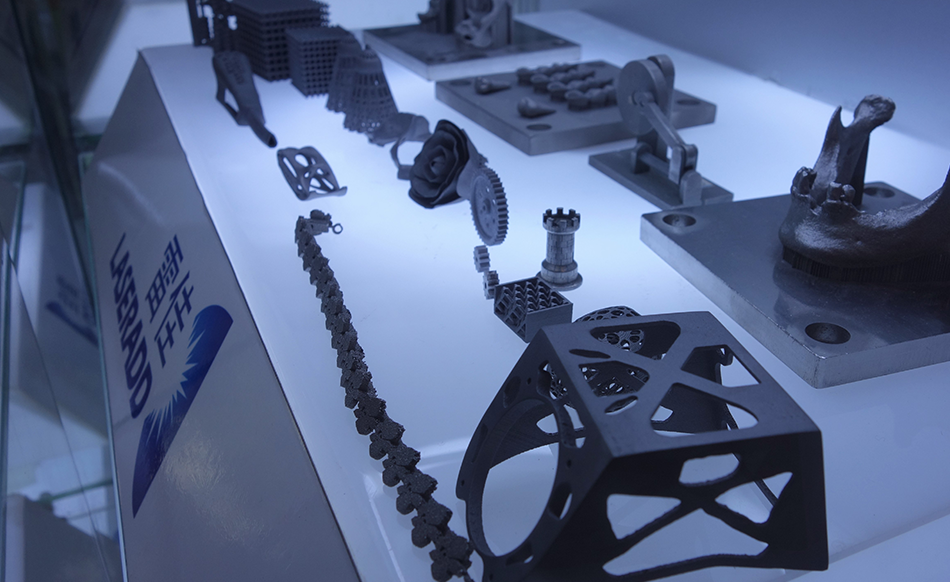

Industrial application

Industrial application3D printing additive manufacturing technology has been widely used in aerospace, mold manufacturing, machinery manufacturing, medical education and other fields. It is praised as the key technology to promote "Industry 4.0" and "Industrial Manufacturing 2025", and to promote the development of revolutionary technology in the industrial industry. 3D printing can be used for product innovation design, complex structure lightweight design, prototype rapid trial production, multi-material structure integrated manufacturing, complex structure product integrated manufacturing, large component composite manufacturing, parts repair and remanufacturing, product review, function verification and so on.

Medical applications

Medical applications3D printing technology is based on the computer 3D model, through the method of stratified discrete software and NUMERICAL control molding, 3D printing technology can produce medical AIDS, artificial implanted scaffolds, tissues and organs and other medical products. The application of 3D printing in the medical industry is the most advanced field of 3D printing technology research at present. It has the characteristics of high flexibility, unlimited quantity and cost saving, which can better meet the individual and precise medical needs in the medical field. Can be used in oral denture, bracket, bracket; Cranial repair; Spinal prosthesis replacement; Sternum repair; Hip replacement; Iliac bone repair; Knee prosthesis; Customized prosthetics, as well as customized orthopedic prosthesis, stent, surgical guide plate, etc.

Accessories order

Accessories orderIn recent years, with the rapid development of 3D printing technology, the innovative application of 3D printing in jewelry and other professional fields has made breakthroughs, creating favorable opportunities for personalized and intelligent jewelry industry. Nowadays, the global jewelry industry is in the stage of upgrading and transformation, and the jewelry sales through traditional channels can hardly meet the personalized needs of young consumers. Many trend-chasing young consumers are keen on showing their individuality, so customization of jewelry based on personal preference and taste has become a consumption way for young consumer groups at present. Jewelry has the characteristics of "small batch", "small size", "high precision", "complex modeling", etc. 3D printing technology is highly consistent with these characteristics, and can directly print high-precision and complex craft jewelry model.

Guangzhou Laseradd Additive Technology Co., LTD., located in Guangzhou (international) Scientific and technological Achievement Transformation Base, Tianhe District, Guangzhou, is a high-tech enterprise specializing in metal 3D printing equipment r&d, manufacturing, sales and metal 3D printing services.

Learn More