2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Composite material is a scientific and technological product in modern engineering materials that has attracted much attention. Because it has many characteristics such as light weight, high strength, corrosion resistance, weather resistance, low thermal conductivity and so on, and can be produced by different processing methods according to different output and use, with high design freedom. At present, it has been widely used in aerospace, boats, vehicles, construction, electronics, electrical machinery, sports and leisure, engineering facilities and other aspects, has gradually replaced the traditional materials, and become an important structural material.

1. Principle of ordered 3D composite laser selective melting technology

Ordered 3D composite laser selective melting (SLM) technology is an additive manufacturing method which uses high energy laser beam to melt metal alloy powder on 2d cross section and print solid parts layer by layer. The 3d model was designed by CAD software, and the STL file format was exported that could be recognized by slicing software. The section profile data of the 3D model was obtained by slicing and adding support and hierarchical processing. The path planning software was used to scan the profile data. The path planning data is imported into the laser selective melting equipment, and the industrial computer controls the laser beam selection to melt metal powder materials layer by layer according to the scanning path of each layer contour. Each layer of powder can control different powder materials through the funnel, and finally stacked into a dense THREE-DIMENSIONAL metal parts entity layer by layer.

2, industrial grade ordered 3D composite material forming equipment Dimetal-100

Recently, in the field of multi-material research, Guangzhou Lejia Additive Technology Co., Ltd. has developed an industrial-grade multi-material metal 3D printing device, Dimetal-100, which uses laser selective melting technology to realize the ordered arrangement of dissimilar powders, that is, the orderly arrangement of powder A on the powder layer B.

The ordered powder laying device can realize the ordered arrangement of powder A, that is, in addition to the traditional scraping plate laying powder layer, the addition of the ordered powder laying device can realize the ordered arrangement of powder A on the powder layer B, so as to achieve the formation of ordered composite materials, to achieve the laser forming of arbitrary gradient materials. Industrial grade multi-material metal 3D printing equipment Dimetal-100 has innovative reference in composite materials. It can be used for laser forming of ordered composite materials, realizing the quantitative distribution of different materials in gradient materials, and also widely used in cutting tool forming, such as grinding wheel forming.

At present, the company has preliminarily developed the ordered powder dispensing device, and verified the feasibility of its function, and is currently improving the structure and system development of the equipment.

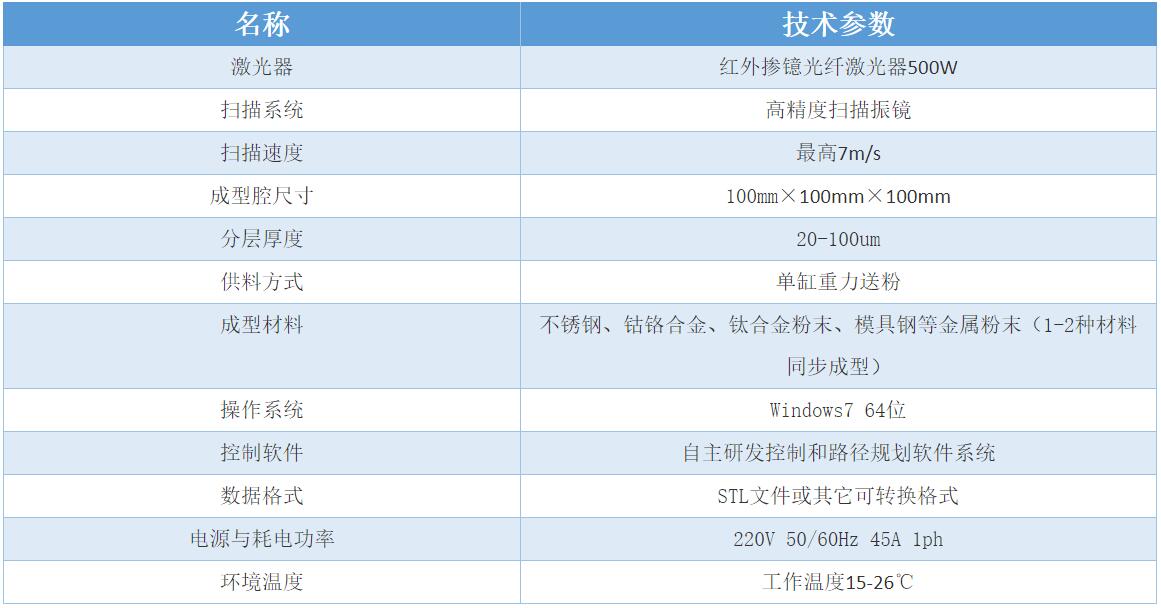

Table 1 Key technical parameters of equipment