2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

In recent years, with the rapid development of economy, the public enthusiasm for 3 d printing technology is also more and more high, automotive, medical, domestic outfit have produced a batch of another batch of imagination of 3 d printing products, early application in the field of aerospace metal 3 d printing more in the market, such as industry, automobile, oral cavity, mold, Metal 3D printing technology provides more new ideas for industrial design and has a subversive significance for traditional manufacturing design.

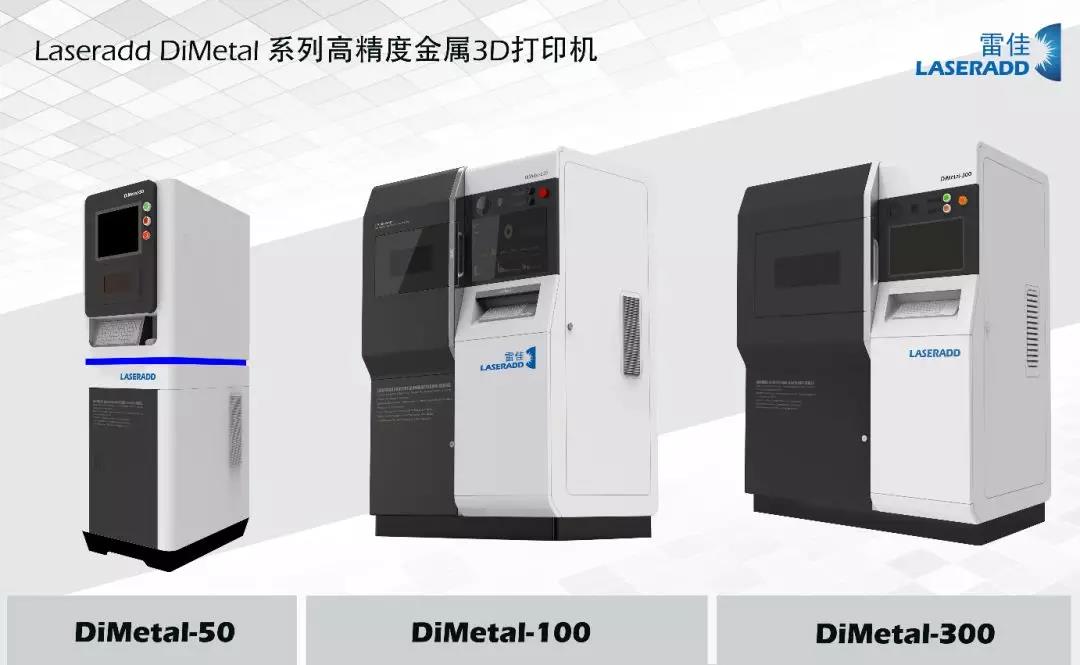

As the fastest growing technology in industrial 3D printing — SLM (Laser selective melting) technology, the industry has been placing high hopes on the innovation team of Guangzhou Lejia more than ten years of concentration on industrial product development, launched a series of Laseradd industrial metal 3D printers, what is the special features of The Laseradd series products launched by Lejia? Let’s take a look.

SLM is one of the most important parts of 3D printing. It is based on discrete stacking, where a laser melts a pre-programmed metal powder layer by layer until the part is printed. Lejia METAL 3D printer uses fine focused light spot to scan 15-53 micron metal powder, can print any shape, can directly shape the traditional processing process can not process the functional parts, density can reach more than 99%, size accuracy can reach 20 micron, is one of the most advanced metal 3D printing technology in China. It can be used in aerospace, nuclear power, medicine, jewelry, scientific research and education, etc.

Laser scanning path planning and process control

Molding parts are composed of many layers formed surface overlay, and each layer of the article is composed of many single forming surface melting woven, single channel single scan line and all kinds of powder molding surface overlay in law is the key to the parts finished product density, tensile strength, in view of the titanium alloy, stainless steel, cobalt chromium alloy, such as material, mine better targeted scan path and overlay scheme is designed. The self-developed scan path planning software adds scan optimization of any Angle on the basis of the common 90-degree scan, which can realize the modification of scan spacing, selection of scan strategy and optimization of material scanning scheme.

Energy input control

Generally, the higher the laser energy input, the easier it is to obtain a smooth and continuous single channel, but the high laser power density tends to make the material gasification, which not only reduces the material quality in the pool, but also blows away the powder around the pool, resulting in the next scan, there is not enough powder to ensure the fullness of the pool. Through tens of thousands of tests, lejia additive summarizes the SLM forming energy parameters of various materials, and sets the over-melting, incomplete melting and reasonable energy input range of the molten pool.

Forming scan strategy

The scanning strategy plays an important role in improving the density and forming quality of SLM molded parts and reducing the internal residual stress. Lejia company adopts different scanning speed and laser power for the outer contour and inner layer of parts, which greatly improves the forming efficiency and can obtain molded parts with high density and high surface quality.

Support design

SLM forming metal parts, most of time need to add the support structure, and support the way of adding a great influence on forming quality of metal parts, especially the suspension structure, mine better increase material adopt modified generated software can support type, support density, local characteristics, to ensure forming metal parts to get off smoothly from the substrate, can guarantee the quality of drape structure of molding.